Bottom Hole Assembly (BHA): The combination of tooling assembled at the leading edge of a drill string. Can include: the drill bit, downhole motor, subs, survey probe, nonmagnetic collars, reamers, barrels.

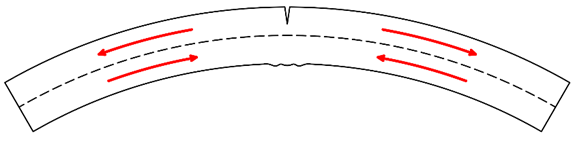

Design Radius: The nominated IFC radius. The nominated radius should include a suitable factor of safety based on project risk appetite, construction method and geotechnical conditions to increase the radius over the minimum radius and ensure yielding and deformation does not occur.

Depth of Cover: Vertical measurement from the top of pipe to the current surface level.

Drill Bit: The tool used during pilot operations that cuts soil or rock at the leading edge of a drill string.

Drilling Fluid: A mixture of water and viscosity products (bentonite and/ or polymers) pumped through the drill rig, down through the drill pipe and out of the drill bit or reamer to aid cutting, transport cuttings, stabilise the borehole, cool cutters, and reduce friction.

Drill Pipe: Tubular steel lengths fitted with threaded ends, tool joints. The drill pipe connects the horizontal drilling rig with the drill bit or reamer. The drill pipe both pumps drilling fluid and advances/ retracts the drill bit or reamer.

Carrier Pipe: see Product Pipe.

Conduit: a pipe that acts as a housing for cables.

Enveloper: a pipe that encases a product pipe.

HDPE: High density polyethylene, elastic polymer used to make a variety of products including pipe.

Horizontal Directional Drilling (HDD): A form of trenchless excavation and pipe installation. The equipment and procedures have been developed to minimise surface damage, with little or no interruption of other existing lines or services. Works are undertaken in three phases: (1) pilot hole, (2) reaming and (3) pipe installation. Horizontal directional drilling requires a specialised drilling rig with ancillary tools and equipment.

IFC: Issued for Construction, documents issued ready for use, no changes required.

Minimum Radius: The radius at which bending stress induces permanent deformation. A section can undergo temporary elastic bending until it reaches the yield stress limit, after this point permanent deformation occurs with microscopic fracturing in the tensile component and buckling in the compressive component. The whole section may then result in stress hardening becoming brittle, become bent, cause ovality or result in section being kinked.

Modulus of Elasticity: A material property, measure of stiffness or elasticity, ability to resist deformation.

Product Pipe: a pipe which has a gas or fluid flowing through it, also referred to as a Carrier Pipe.

Reamer: A cutting tool pushed or pulled through the borehole to enlarge it to a diameter sufficient for pipe installation. Reamer type varies according to geotechnical conditions to suit different formations.

Safe Pull Stress: The yield stress including reduction factors for combination loading during pipe installation for HDD methods.

Steering Tool: A device at the leading end of the drill string, aka “probe”, that measures inclination, azimuth, and orientation which the driller uses to steer the string along the design profile.

Surface Casing: a steel encasing pipe that is used at the entry or exit of a HDD crossing to stabilise the surrounding formation. Can be used for hydrofracture containment or settlement prevention. Can be installed via several methods including cut-and-lay, hammer, and washover.

Trenchless: Refers to the group of pipe installation methods that require minimal surface excavation or disturbance. Includes a variety of different methods including HDD, auger boring, pipe jacking, hammering, microtunnelling, pipe bursting and relining. The inverse, traditional trenching, involves excavation of a trench along the pipe route, lowering the pipe into the trench, and backfilling which requires access vertically above the pipe. Trenchless operations can be offset and do not require direct access vertically above the pipe.

Yield: Material property, the stress at which the material begins to deform plastically, when forces are removed, it does not return to its original form.

Other questions?

Contact us here.